If you’re wondering how to use a circular saw without a table, then you’ve come to the right place. However, it is essential to point out that there are various types of circular saws, each one assembled with different power ratings. The characteristic round shape combined with a circular blade with small sharp teeth helps tear through the wood, essentially splitting it into multiple pieces.

Anyone who has used a circular saw or has had to rely on it will attest that there are situations where they need to perform a cutting task using the saw but without a table. Fortunately, it is possible to use a circular saw without a table and see remarkable results. Circular saws are the best saw for cutting 2x4s.

What is a Circular Saw?

A circular saw is one of the most used power tools by carpenters. The saw can be mounted onto a table, or it can be used as a handheld device.

A circular saw is designed to allow the cabinet maker or carpenter to make a myriad of cuts easily. The round blade with sharp metal teeth allows the power tool to slice through various wood types and thicknesses easily. However, circular saws can easily be fitted with several different types of blades, which allow a carpenter to easily slice through lumber, concrete board, paneling and timber.

A circular saw is also one of the best Best Saw for Cutting 2×4 owing to specialized blades that can also cut through sheet metal. Well-designed circular saws offer users the option to adjust the cut’s depth and height, with many designed for bevel cuts.

Since circular saws are handheld, they can be used by both right and left-handed operators. Furthermore, the saw is easily table mounted for added control and stability.

Interested in how one tool compares to the other? Check out our article, Dremel Ultra Saw versus the Saw Max.

How to Use a Circular Saw Without a Table – Step by Step Instructions

Now there may be many instances when you need to use a circular but without having to mount it on a table. Fortunately, regardless of the circular saw you are using, it is easy if you know-how. One effective way we recommend is to use a couple of saw horses to do the job. Saw horses make cutting very easy, since they provide stability for the board while you focus on the controlling the saw.

Step 1:

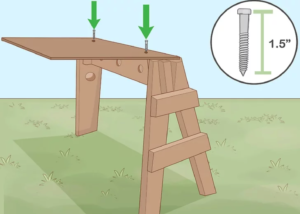

Spread the saw horses out in your workspace, letting the board rest over them.

Step 2:

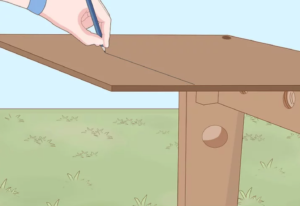

You will want to add an edge guide to the saw to make an even cut while moving parallel with the wood or plywood. You can use a speed square, combination square, or a similar tool. These tools are essentially just rulers to use prior to cutting. Try and keep your guideline it as even as possible.

Step 3:

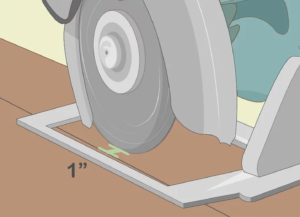

You also want to set the blade depth correctly to touch wood and then cut through it. You will want to get one that has a quarter-inch depth. Simply bring the circular saw over to the part of the board you wish to cut. Remember that every circular saw has a metal frame around the blade called the shoe. Press your thumb firmly against the tab on the saw’s shoe in front of the blade. Place your index finger underneath the board, then squeeze your fingers together to hold the saw in place.

Step 4:

Keep the blade in the section of wood you plan on cutting off. This will make it easier to cut through from one end to the next. You’ll will want to double-check and make sure that the line you marked on the wood is between the sawhorses.When you cut freehand, the blade can stray. If it cuts past the line, your entire board is ruined.

In some instances, you might need multiple sawhorses depending on the size of what you’re cutting. If the board you’re trying to cut is too thick, you will need many sawhorses to accomplish what you want with precision.

Step 5:

Turn on your saw and cut the board. Press the saw’s shoe down on the board. As the saw cuts, slide your index finger along the board to keep the saw moving along. Monitor the saw closely so you can correct it if it goes off course.

Different Types of Circular Saws

Now there are a few different types of circular saws. Some tend to be more obscure, while others are more common among professional carpenters and DIY enthusiasts. Generally, the Sidewinder, is the most common, followed by the worm drive saw, and the hypoid circular saw.

Disclaimer: as an Amazon Associate, I can earn from qualifying purchases.

The Sidewinder Circular Saw

Of all the Table Saws, the Sidewinder happens to be one of the most common types of circular saws used, especially in eastern states. The Sidewinder has the motor mounted on the side, which allows for a more compact design. Since the motor is on the right side of the tool, it rests between the solid wood piece instead of the cutoff portion.

One of the reasons why the Sidewinder is the saw of choice for many people is that it is lightweight, making it the best tool for cutting jobs. Plus, because the motor happens to be in line with the blade, it translates to more speed, usually around 6k RPM. Some other pluses of this saw are that it’s available in a cordless version, and it does not require adding oil.

The Worm Drive Circular Saw

A worm drive saw has the motor mounted on the back of the tool, making it longer and narrower than the Sidewinder. The power from the motor to the blades is transferred through two gears at a 90-degree angle. While this results in slower blade RPMs (4500 RPM), it does add more torque to the tool.

Many carpenters find the length of the saw handy, especially when cutting broad boards. Also, the shape makes cutting much easier. However, the worm drive requires oil to be added every few months.

The Hypoid Circular Saw

At times the Hypoid Circular saw is mis-categorized as a worm drive saw owing to its similar appearance. While the Hypoid also has the motor located behind the blade, it uses a different power delivery or transmission system.

The saw uses hypoid gears, which are spiral bevel gears that aren’t in-line with a meshing gear axis. Many choose the hypoid saw because it has better power, improved blade contact, and does not make as much noise.

Final Thoughts……

A circular saw is an essential tool for anyone serious about working with wood. While it might seem impossible to use by a newbie, it becomes second nature with some time and practice. The important thing is always to wear the right safety gear and start with a few practice runs before you switch to a commercial or more serious DIY project.

Interested in other articles? Check out…..

How Does a Pneumatic Nail Gun Work