If you’re in the market for a pneumatic nail gun, prior to purchase you may find yourself asking, so how does a pneumatic nail gun work? And possibly, do I even need one? Like many electrical tools, there are always cheaper hand tools that can substitute, but the advantage of the electrical models is speed and efficiency. A good pneumatic nail gun will speed up the job at hand and is very popular for those in construction and the home owners who do a bit of DIY.

Just like a Cordless Finish Nailer, a pneumatic nail gun represents an evolution of the traditional devices and can completely replace tools like Cordless Drill or electric stapler gun. The pneumatic nail gun works with compressed air, which is secured by a compressor. It is always ready to use, and the work can be done quickly and efficiently while saving a huge amount of time. I know I love my pneumatic nailer!

If you want to see how you can use your pneumatic nail gun for DIY woodwork, check our article on Cool Things to Make Out of Wood. Or to get some ideas on what you can do with wood, and maybe earn some money along the way, in our article about Woodworking Projects That Sell.

Is a pneumatic nail gun just like an electric gun?

From the outside, the working technique of these tools can remind those of an electric gun, but in this case, there are few fundamental differences. The first is due to the fact that the pneumatic nail machine is controlled by a compressor that supplies compressed air. Depending on the force provided by the pneumatic tool, the tool has appropriate power and efficiency indicators.

Another feature is structural in nature. To ensure a continuous flow of work, the tank contains a container for loading consumables. These can be nails and staples, and the possibility of using both is not excluded.

How Does a Pneumatic Nail Gun Work? – Step by Step Guide

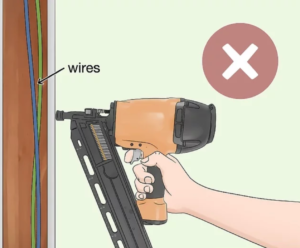

Before you commence, it’s always a good idea to be mindful of safety procedures. Make sure you check for hidden hazards beneath the surface. Wires, pipes, and other hidden things in the wall can make a nail gun malfunction and you could shock yourself or destroy plumbing. Neither would be great!

I tend to knock on a surface to see if it’s solid or hollow. If you’re unsure and need to nail a surface with wires or pipes behind it, check with an electrician or plumber to see if they can be moved out of the way.

Point the gun towards the ground when not in use, and keep it unplugged as you move around

Step 1.

Fastened to the base, the air compressor builds up air pressure from the outside and compresses it to an optimal level within the tool. Pneumatic nail guns have regulators inside the unit that obtain the appropriate amount of pressure.

Step 2.

Before releasing, there is a safety mechanism for powering that will block the compressed air within the unit so that it will not fire unless you press the plunger onto the material.

Step 3.

When you pull the trigger, the air pressure will be released in the chamber, where the hammer lies, attached to a blade. By depressing the plunger onto the material, you enable the compressed air to lift the plunger and push the hammer.

Step 4.

Enough force is created onto the hammer for firing the nail through the barrel. A blade makes sure that only one nail is being fired at a time with one nail shot.

In order to prevent the system from losing the pressure level with continuous usage, the compressor recoils and rebuilds to an optimal level when the pressure drops down to ensure consistent work.

Good Tip:

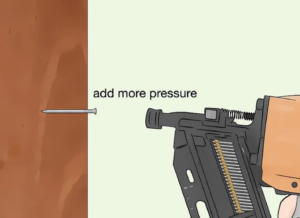

If the nail didn’t go through, turn the pressure up slightly higher by turning the knob on top of the gun. If it damaged the surface with its force or was lost in a wall, turn the pressure down. It may take a bit of trial and error to figure out the correct configuration, so be sure to test the nail gun on a scrap piece of the surface before committing

Which Nailer Is Best For My Project?

Now that you know how does a pneumatic nail gun works, you may ask yourself which nailer is best for my project? Moreover, maybe you are a beginner and are not sure which nailer to use for what project. Nail guns are different based on their size nailers, and what you can do with them.

Because they are thin, brad nailers are mostly used for molding and trimming work, as they are less likely to split fine transitions. Wherever you have a problem with potential wood splitting, brad nailers are the best choice for you.

If you have a large carpentry project in front of you, you cannot go wrong if you choose a coil framing nailer. It will ensure the highest level of quality framing, as it contains 200 to 300 nails in its canister. And you can be sure you will spend lots of nails to secure your framing project.

The most versatile tools on the market are the finish nailers, as they can be used for a variety of projects, from flooring, millwork, and crown molding. If you want a pneumatic nailer for a crown molding job, you may also want to check out our article on the Best Crown Molding Jig.

If you are into DIY hobbies and crafts, a great choice for you would be headless pinners as they create small entry holes, and can also be used for delicate trimming work.

Air Compressor

As mentioned above, this is the main part of a pneumatic nail gun that can make or break your project. It brings the pneumatic nail gun to life, ensuring it is supplied with a compressed air that goes into the nailer air reservoir. They can be powered by gasoline or electricity, and depending on where you will use your pneumatic nail gun, you can choose based on the size, power, and additional features.

It is important to use one with the correct power for the project you will use – for example, if you decide on the electric one, it should be as close to the workplace as possible. If that is not possible if you do not have a heavy-duty cord or the electricity is not an option on your job site, you may want to switch your choice to a gas-powered unit.

Next, you may want to be confused about whether to choose a small or large tank size. You should know if you plan to use more than one tool connected to the air compressor. If you will use more than one tool, consider buying a larger tank size air compressor as the more air will be used. There are great models you can choose from on the market, with low operating noise and additional available features such as trays or multi-tool use.

The supply of pneumatic nail guns on the market is quite wide and the consumer has the opportunity to choose from a variety of budget-friendly models for its needs. Although it may look like they are used only in professional shops and workrooms, the practice suggests otherwise. They save precious minutes when used in simple repairs so that you can spend your time on more important things.

Interested in other posts? You may also want to check out:

How to Use a Circular Saw Without a Table

How Much Does A Woodworker Make?